UNDERSTANDING TOOL FORMATS

Eliminates paraffin and scale without chemicals

UNDERSTANDING TOOL FORMATS

Eliminates paraffin and scale without chemicals

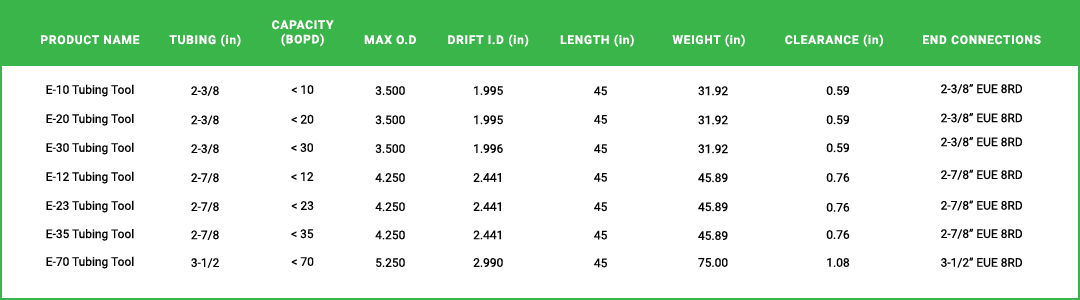

Introducing the Enercat Tool

Enercat works with any pumping system, including Electrical Submersible Pumps (ESP). Each application is customized for the specific well depending upon tubing size and fluid volume. Enercat will typically be run either below the pump intake or above the pump discharge, or as a tail joint at the end of the tubing string.

Easy to install, EnercatTM requires no external power, maintenance or servicing and has no internal restrictions. EnercatTM is, quite simply, the next level oil well optimization. Clients who switch from aspaltene and paraffin removal chemicals to EnercatTM save on significant annuals costs.

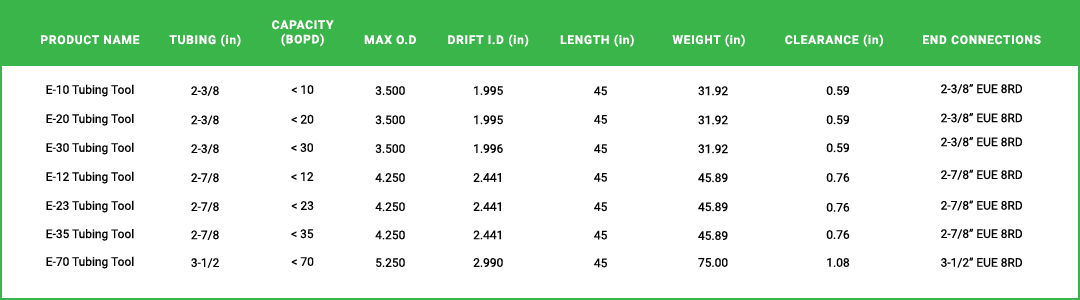

2-3/8" Tubing Size

E-10 Tubing Tool (10 BOPD)

E-20 Tubing Tool (20 BOPD)

E-30 Tubing Tool (30 BOPD)

2-7/8" Tubing Size

E-12 Tubing Tool (12 BOPD)

E-23 Tubing Tool (23 BOPD)

E-35 Tubing Tool (35 BOPD)

3-1/2" Tubing Size

E-70 Tubing Tool (70 BOPD)

Introducing the Enercat Tool

Enercat works with any pumping system, including Electrical Submersible Pumps (ESP). Each application is customized for the specific well depending upon tubing size and fluid volume. Enercat will typically be run either below the pump intake or above the pump discharge, or as a tail joint at the end of the tubing string.

Easy to install, EnercatTM requires no external power, maintenance or servicing and has no internal restrictions. EnercatTM is, quite simply, the next level oil well optimization. Clients who switch from aspaltene and paraffin removal chemicals to EnercatTM save on significant annuals costs.

Introducing the

Enercat Tool

Enercat works with any pumping system, with the exception of Electrical Submersible Pumps. Each application is customized for the specific well depending upon tubing size and fluid volume. Enercat will typically be run either below the pump intake or above the pump discharge, or as a tail joint at the end of the tubing string.

Easy to install, EnercatTM requires no external power, maintenance or servicing and has no internal restrictions. EnercatTM is, quite simply, the next level oil well optimization. Clients who switch from aspaltene and paraffin removal chemicals to EnercatTM save on significant annuals costs.

2-3/8″ Tubing Size

E-10 Tubing Tool (10 BOPD)

E-20 Tubing Tool (20 BOPD)

E-30 Tubing Tool (30 BOPD)

2-7/8″ Tubing Size

E-12 Tubing Tool (12 BOPD)

E-23 Tubing Tool (23 BOPD)

E-35 Tubing Tool (35 BOPD)

3-1/2″ Tubing Size

E-70 Tubing Tool (70 BOPD)

Introducing the

Enercat Tool

Enercat works with any pumping system, with the exception of Electrical Submersible Pumps. Each application is customized for the specific well depending upon tubing size and fluid volume. Enercat will typically be run either below the pump intake or above the pump discharge, or as a tail joint at the end of the tubing string.

Easy to install, EnercatTM requires no external power, maintenance or servicing and has no internal restrictions. EnercatTM is, quite simply, the next level oil well optimization. Clients who switch from aspaltene and paraffin removal chemicals to EnercatTM save on significant annuals costs.

2-3/8″ Tubing Size

E-10 Tubing Tool (10 BOPD)

E-20 Tubing Tool (20 BOPD)

E-30 Tubing Tool (30 BOPD)

2-7/8″ Tubing Size

E-12 Tubing Tool (12 BOPD)

E-23 Tubing Tool (23 BOPD)

E-35 Tubing Tool (35 BOPD)

3-1/2″ Tubing Size

E-70 Tubing Tool (70 BOPD)

Application Overview

- The Enercat Tubing Tool Series is developed for oil and gas applications and are designed for tubing deployments.

- Containing proprietary technology encased in a sealed chamber, EnercatTM emits a tuned frequency that drives physical changes at the molecular level as fluids pass by the tool to prevent paraffin, scale, asphaltene, and heavy oil.

- The tools are fabricated using nickel coating for corrosion resistance and built on a standard 4′ pup joint with API, EUE threads and standard API drift that is protected by a metal cover and end caps.

- Easy to install and requires no external power, maintenance or servicing and has no internal restrictions and works with any pumping system and suitable in wells equipped with ESP when following a modified installation procedure.

- The tool needs to be installed as close to the perforations as possible, so it can treat the oil before it experiences a significant pressure and temperature drop as it goes up the well.

- Multiple tools can be joined together to increase BOPD capacity.

Application Overview

- The Enercat Tubing Tool Series is developed for oil and gas applications and are designed for tubing deployments.

- Containing proprietary technology encased in a sealed chamber, EnercatTM emits a tuned frequency that drives physical changes at the molecular level as fluids pass by the tool to prevent paraffin, scale, asphaltene, and heavy oil.

- The tools are fabricated using nickel coating for corrosion resistance and built on a standard 4′ pup joint with API, EUE threads and standard API drift that is protected by a metal cover and end caps.

- Easy to install and requires no external power, maintenance or servicing and has no internal restrictions and works with any pumping system and suitable in wells equipped with ESP when following a modified installation procedure.

- The tool needs to be installed as close to the perforations as possible, so it can treat the oil before it experiences a significant pressure and temperature drop as it goes up the well.

- Multiple tools can be joined together to increase BOPD capacity.

Enercat Trim Tool Series

E-5 Trim Tool

5 BOPD – 1.5″ x 12″

E-10 Trim Tool

10 BOPD – 1.5″ x 16″

E-20 Trim Tool

20 BOPD – 1.5″ x 28″

E-40 Trim Tool

40 BOPD – 1.5″ x 48″

Application Overview

- The Enercat Trim Tool Series is developed for oil and gas applications and are used in several configurations

- Containing proprietary technology encompassed around a thin-walled tube, emits a tuned frequency that drives physical changes at the molecular level as fluids pass by the tool to prevent paraffin, scale asphaltene and heavy oil

- The tools are fabricated using stainless steel for corrosion resistance and consists of a composite material encased in a 1.500″ O.D. thin-walled tube

- Easy to install and requires no external power, maintenance or servicing. Placement of the tool is critical as fluid must pass by the Trim Tool to ensure treatment

- The Trim Tool Series is designed to mate with a variety of accessories for deployment in rod pump wells, plunger lift wells, even surface applications

- Treatment capacity is based on BOPD and not BWPD or total fluid as water is a conductor and oil is an insulator

- Multiple tools can be joined together to increase BOPD capacity

Enercat Trim Tool Series

E-5 Trim Tool

5 BOPD – 1.5″ x 12″

E-10 Trim Tool

10 BOPD – 1.5″ x 16″

E-20 Trim Tool

20 BOPD – 1.5″ x 28″

E-40 Trim Tool

40 BOPD – 1.5″ x 48″

Application Overview

- The Enercat Trim Tool Series is developed for oil and gas applications and are used in several configurations

- Containing proprietary technology encompassed around a thin-walled tube, emits a tuned frequency that drives physical changes at the molecular level as fluids pass by the tool to prevent paraffin, scale asphaltene and heavy oil

- The tools are fabricated using stainless steel for corrosion resistance and consists of a composite material encased in a 1.500″ O.D. thin-walled tube

- Easy to install and requires no external power, maintenance or servicing. Placement of the tool is critical as fluid must pass by the Trim Tool to ensure treatment

- The Trim Tool Series is designed to mate with a variety of accessories for deployment in rod pump wells, plunger lift wells, even surface applications

- Treatment capacity is based on BOPD and not BWPD or total fluid as water is a conductor and oil is an insulator

- Multiple tools can be joined together to increase BOPD capacity

Enercat Trim Tool Series

E-5 Trim Tool

5 BOPD – 1.5″ x 12″

E-10 Trim Tool

10 BOPD – 1.5″ x 16″

E-20 Trim Tool

20 BOPD – 1.5″ x 28″

E-40 Trim Tool

40 BOPD – 1.5″ x 48″

Application Overview

- The Enercat Trim Tool Series is developed for oil and gas applications and are used in several configurations

- Containing proprietary technology encompassed around a thin-walled tube, emits a tuned frequency that drives physical changes at the molecular level as fluids pass by the tool to prevent paraffin, scale asphaltene and heavy oil

- The tools are fabricated using stainless steel for corrosion resistance and consists of a composite material encased in a 1.500″ O.D. thin-walled tube

- Easy to install and requires no external power, maintenance or servicing. Placement of the tool is critical as fluid must pass by the Trim Tool to ensure treatment

- The Trim Tool Series is designed to mate with a variety of accessories for deployment in rod pump wells, plunger lift wells, even surface applications

- Treatment capacity is based on BOPD and not BWPD or total fluid as water is a conductor and oil is an insulator

- Multiple tools can be joined together to increase BOPD capacity

Eliminate paraffin and scale without chemicals.

Eliminate paraffin and scale without chemicals.

Eliminate paraffin and scale without chemicals.

Enercat in the Wild

Enercat tools are used in 24 countries and have recently been adopted by many large U.S. producers as their standard well optimization solution.