CASE STUDIES

Real Data. Real Results.

CASE STUDIES

Real Data. Real Results.

Paraffin Prevention in Delaware Basin

The Issue

A leading US Independent Oil and Gas Producer was experiencing extreme paraffin problems in their Delaware Basin operations of Texas and New Mexico. Conventional chemical programs deployed for prevention & remediation and hot water treatments for remediation were met with poor success and high operating costs. Paraffin related failures caused the Producer to pull wells prematurely, lose oil production during downtime, handle operational challenges in restoring production in failed wells and cope with high flowline pressures.

The Solution

The Independent Oil and Gas Producer engaged the Enercat Technology Group to install Enercat Downhole Tools for a 130-day trial in 2 wells experiencing extreme paraffin deposition problems. The Enercat Downhole Tool is a novel yet proven technology that lowers Wax Appearance & Pour Point temperatures and impedes the paraffin crystallization process by weakening the intermolecular London Dispersion forces that govern precipitation, crystallization, and wax deposition in paraffinic crudes.

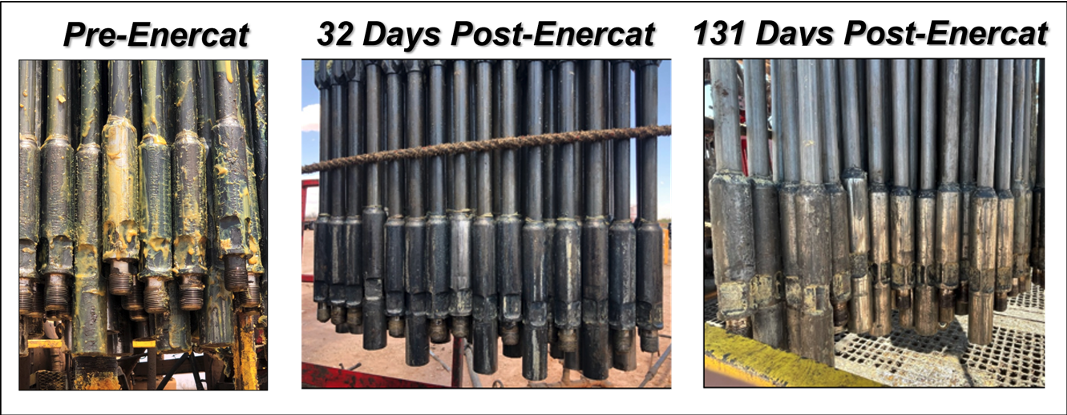

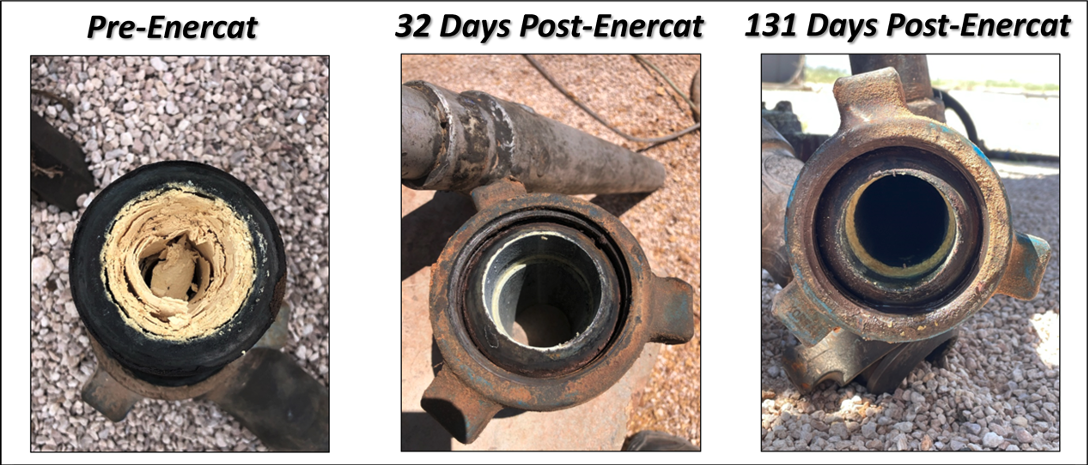

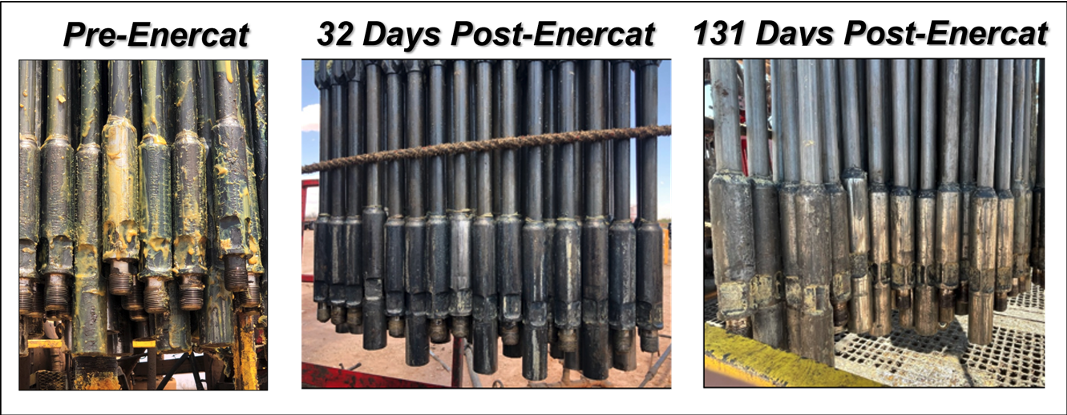

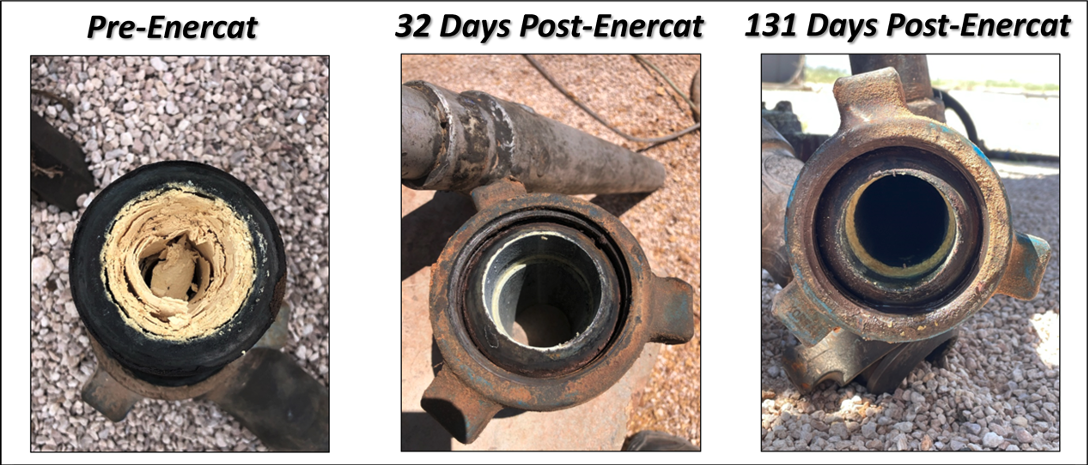

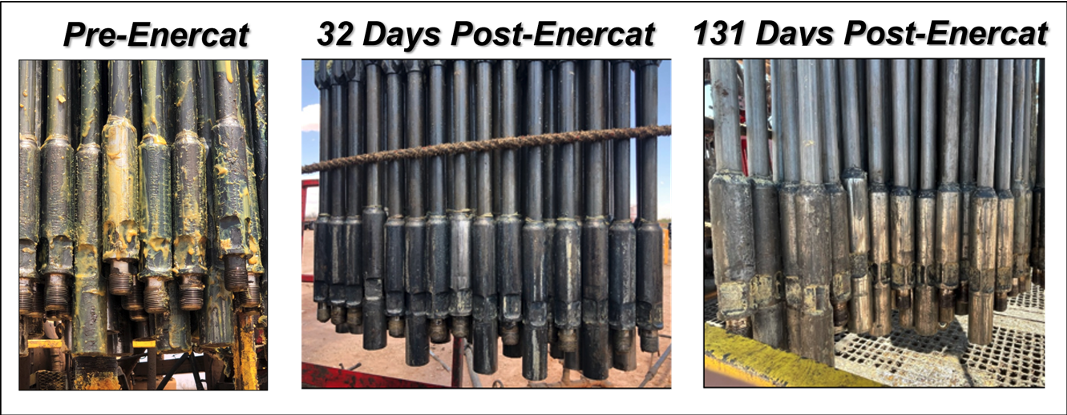

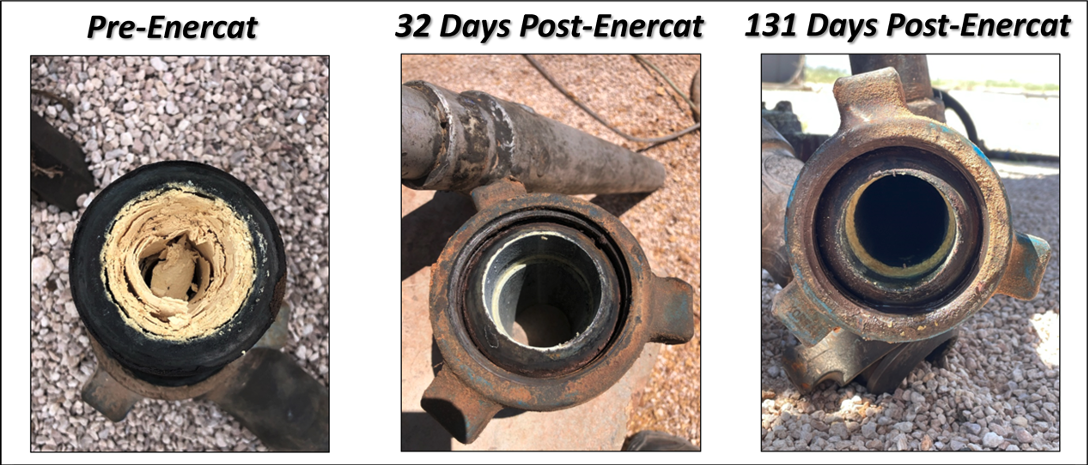

The results of the trial in paraffin prevention in downhole production equipment and at surface flowline facilities were extraordinary. After 30 days post-Enercat installation there was little to no paraffin build-up on the rods and only very slight paraffin forming on steel couplings and rods after 130 days post-Enercat installation. There was no paraffin deposition in surface flowlines at 32 days post-Enercat installation nor at 131 days post-Enercat installation.

Commercial Benefit and Producer’s Endorsement

The leading US Independent Oil and Gas Producer provided the Enercat Technology Group with a post-mortem analysis of the 130-day 2 well trial:

- Conventional chemical programs were not used after the Enercat tools were installed resulting in 100% cost savings.

- No hot water treatments were required to restore production in well failures.

- Flow lines were clean with no paraffin deposition.

- No lost production due to paraffin related downtime.

The Producer enthusiastically endorsed the Enercat Downhole Tool, proclaiming that “it would take years for a paraffin related failure to occur based on the slight paraffin build-up seen on rods after 133 days”.

Moreover, after a thorough evaluation of the Enercat tool’s performance by the chief production engineer in concurrence with the production foreman and rig consultant, the chief engineer declared “I find Enercat tools to be the best paraffin prevention method and should be used as the first line of defence.”

Reducing Paraffin Build-up on Rods

Eliminating Paraffin Build-up in Flowlines

Paraffin Production During Initial Rod Pulling

Oil Production Increases in Paraffin-Rich Kansas

Tool Installation Program

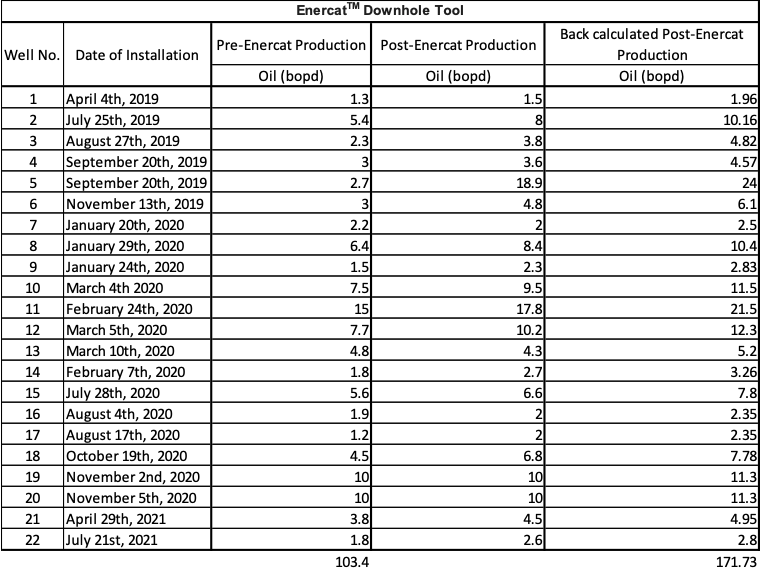

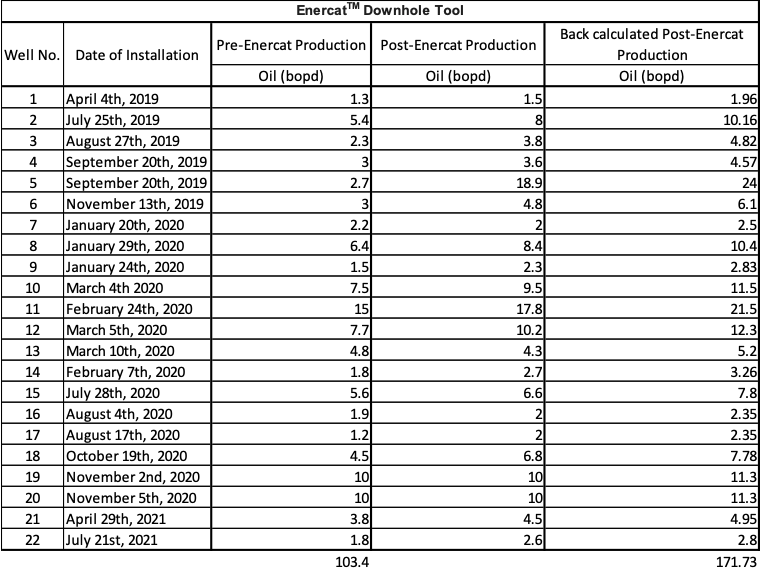

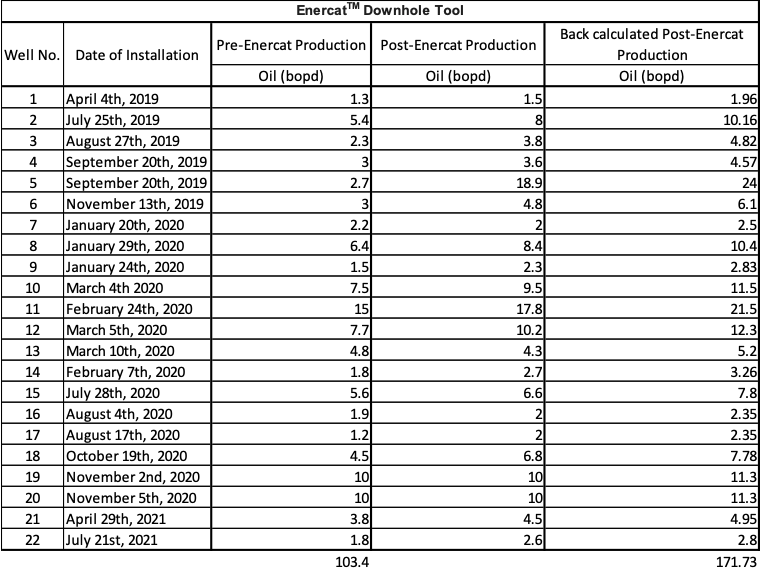

A small independent Mid-Continent producer installed the Enercat Downhole Tool in 22 of their Kansas stripper wells between April 2019 and September 2021. The wells were experiencing ongoing paraffin deposition causing interruptions to production and costs associated with the need for recurrent hot oiling and chemical treatments. The Enercat tools were not installed for the purposes of a trial; the company was already satisfied with the efficacy of the Enercat Tool in producing their medium light paraffin-rich crude oils. As such the company did not monitor the post-Enercat crude oil production in the weeks following installation of each of the tools but instead measured the production in all 22 wells in March of 2022. Some of the wells therefore produced for more than two and half years after tool installation and most wells produced for more than one and a half years before their production rates were measured.

Results

The results of the Enercat tool installations were highly successful and despite the long delay in measuring the production performance of each of the wells, eighteen of them were still producing above the commencement rate, two remained level and two wells were marginally lower. The overall production increase was 39.3 BOPD or 39.3% higher. These results represent the minimum benefit of the production increases because all wells naturally decline over time and production rates shortly after tool installation would undoubtedly have been much higher.

Company’s Summary

The company provided a general summary of the results of the installation program: In addition to the revenue from production increases, the wells produced free of paraffin deposition and all chemicals and outside interventions were discontinued.

- Cost of the Enercat tools for the 22 wells was approximately $130,000

- The company realized more than $1,000,000 in oil sales revenue due to production increases.

- Operating costs were significantly reduced.

Discussion

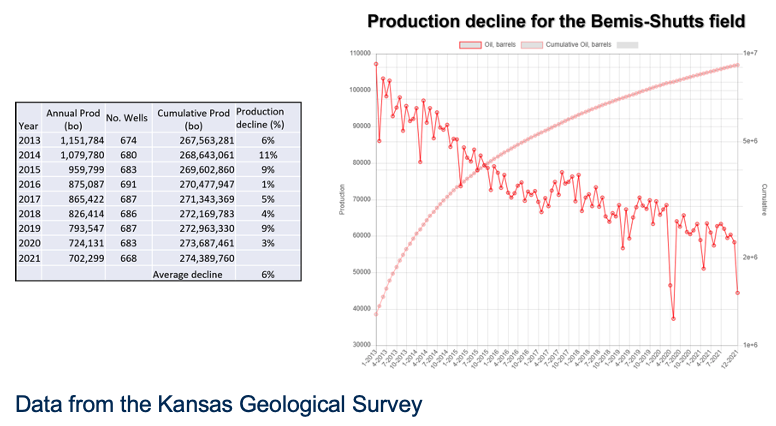

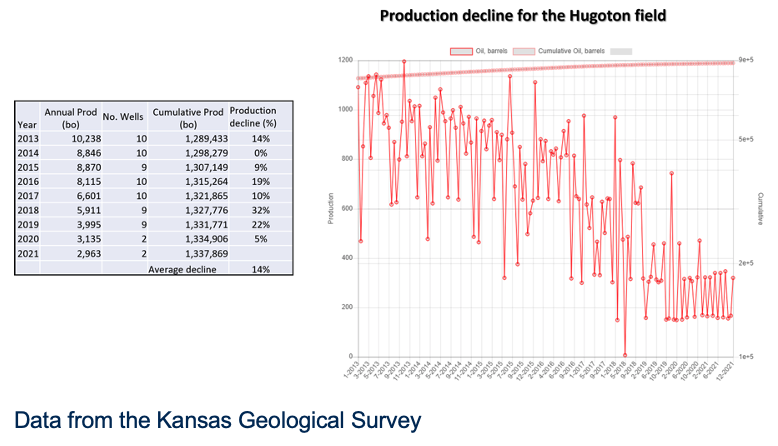

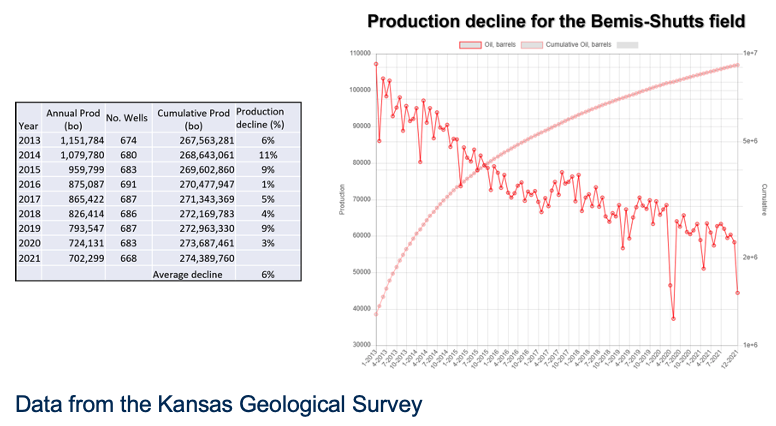

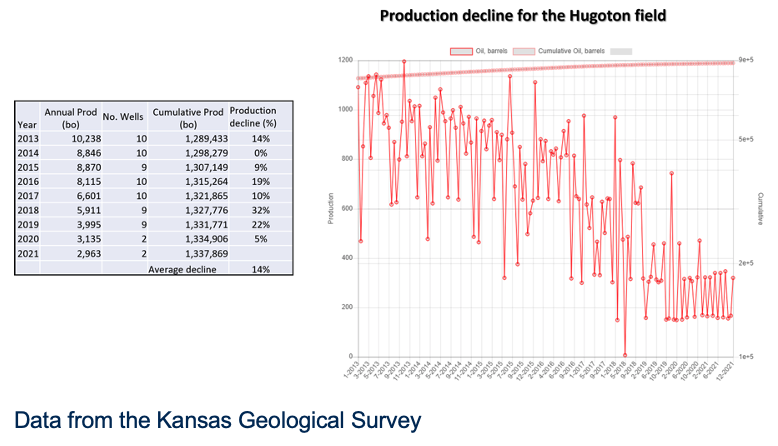

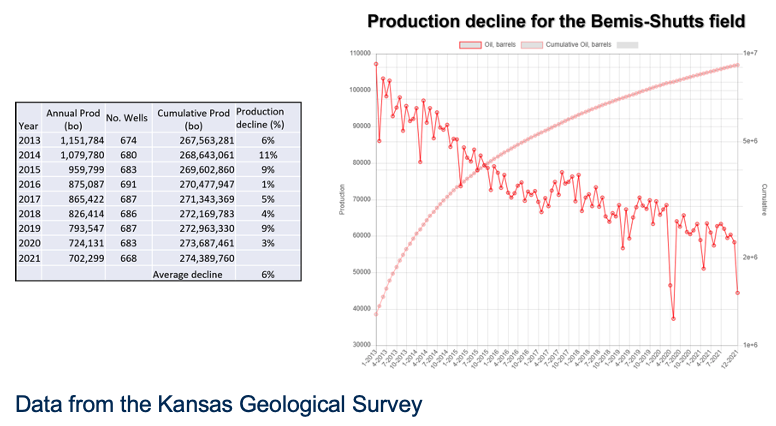

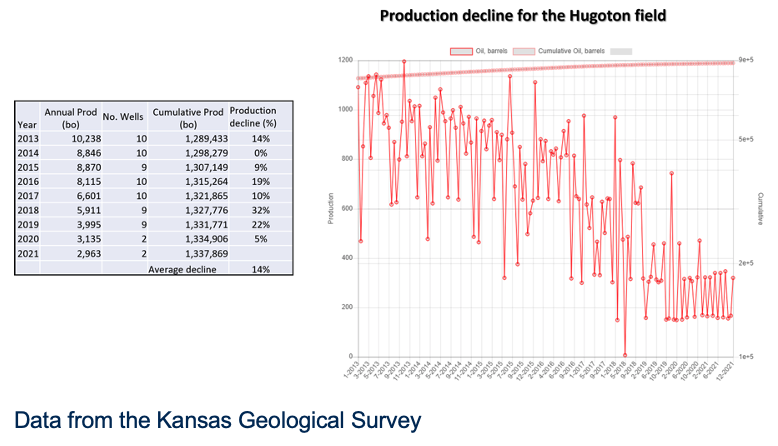

Because oil field production declines naturally it is possible to approximate what production rates of the 22 wells would have been shortly after tool installation by understanding the decline rate of the fields from which they produce. The vast majority of the Enercat installed wells produce from the Bemis-Stutts and Hugoton fields. The production decline at Bemis-Stutts field averaged 6% per annum from 2013 to 2021 and 14% at Hugoton field. Taking the average production decline of both fields gives a 10% annual production decline. Applying this average annual decline enables a reasonable back calculation of what each well was probably producing shortly after installation of the Enercat tool. On this basis, the overall production increase was 68.3 BOPD or 66% higher.

Production Response

Production Decline at Bemis-Stutts Field

Production Decline at Hugoton Field

Paraffin Prevention in Delaware Basin

The Issue

A leading US Independent Oil and Gas Producer was experiencing extreme paraffin problems in their Delaware Basin operations of Texas and New Mexico. Conventional chemical programs deployed for prevention & remediation and hot water treatments for remediation were met with poor success and high operating costs. Paraffin related failures caused the Producer to pull wells prematurely, lose oil production during downtime, handle operational challenges in restoring production in failed wells and cope with high flowline pressures.

The Solution

The Independent Oil and Gas Producer engaged the Enercat Technology Group to install Enercat Downhole Tools for a 130-day trial in 2 wells experiencing extreme paraffin deposition problems. The Enercat Downhole Tool is a novel yet proven technology that lowers Wax Appearance & Pour Point temperatures and impedes the paraffin crystallization process by weakening the intermolecular London Dispersion forces that govern precipitation, crystallization, and wax deposition in paraffinic crudes.

The results of the trial in paraffin prevention in downhole production equipment and at surface flowline facilities were extraordinary. After 30 days post-Enercat installation there was little to no paraffin build-up on the rods and only very slight paraffin forming on steel couplings and rods after 130 days post-Enercat installation. There was no paraffin deposition in surface flowlines at 32 days post-Enercat installation nor at 131 days post-Enercat installation.

Commercial Benefit and Producer’s Endorsement

The leading US Independent Oil and Gas Producer provided the Enercat Technology Group with a post-mortem analysis of the 130-day 2 well trial:

- Conventional chemical programs were not used after the Enercat tools were installed resulting in 100% cost savings.

- No hot water treatments were required to restore production in well failures.

- Flow lines were clean with no paraffin deposition.

- No lost production due to paraffin related downtime.

The Producer enthusiastically endorsed the Enercat Downhole Tool, proclaiming that “it would take years for a paraffin related failure to occur based on the slight paraffin build-up seen on rods after 133 days”.

Moreover, after a thorough evaluation of the Enercat tool’s performance by the chief production engineer in concurrence with the production foreman and rig consultant, the chief engineer declared “I find Enercat tools to be the best paraffin prevention method and should be used as the first line of defense.”

Reducing Paraffin Build-up on Rods

Eliminating Paraffin Build-up in Flowlines

Paraffin Production During Initial Rod Pulling

Oil Production Increases in Paraffin-Rich Kansas

Tool Installation Program

A small independent Mid-Continent producer installed the Enercat Downhole Tool in 22 of their Kansas stripper wells between April 2019 and September 2021. The wells were experiencing ongoing paraffin deposition causing interruptions to production and costs associated with the need for recurrent hot oiling and chemical treatments. The Enercat tools were not installed for the purposes of a trial; the company was already satisfied with the efficacy of the Enercat Tool in producing their medium light paraffin-rich crude oils. As such the company did not monitor the post-Enercat crude oil production in the weeks following installation of each of the tools but instead measured the production in all 22 wells in March of 2022. Some of the wells therefore produced for more than two and half years after tool installation and most wells produced for more than one and a half years before their production rates were measured.

Results

The results of the Enercat tool installations were highly successful and despite the long delay in measuring the production performance of each of the wells, eighteen of them were still producing above the commencement rate, two remained level and two wells were marginally lower. The overall production increase was 39.3 BOPD or 39.3% higher. These results represent the minimum benefit of the production increases because all wells naturally decline over time and production rates shortly after tool installation would undoubtedly have been much higher.

Company’s Summary

The company provided a general summary of the results of the installation program: In addition to the revenue from production increases, the wells produced free of paraffin deposition and all chemicals and outside interventions were discontinued.

- Cost of the Enercat tools for the 22 wells was approximately $130,000

- The company realized more than $1,000,000 in oil sales revenue due to production increases.

- Operating costs were significantly reduced.

Discussion

Because oil field production declines naturally it is possible to approximate what production rates of the 22 wells would have been shortly after tool installation by understanding the decline rate of the fields from which they produce. The vast majority of the Enercat installed wells produce from the Bemis-Stutts and Hugoton fields. The production decline at Bemis-Stutts field averaged 6% per annum from 2013 to 2021 and 14% at Hugoton field. Taking the average production decline of both fields gives a 10% annual production decline. Applying this average annual decline enables a reasonable back calculation of what each well was probably producing shortly after installation of the Enercat tool. On this basis, the overall production increase was 68.3 BOPD or 66% higher.

Production Response

Production Decline at Bemis-Stutts Field

Production Decline at Hugoton Field

Paraffin Prevention

in Delaware Basin

The Issue

A leading US Independent Oil and Gas Producer was experiencing extreme paraffin problems in their Delaware Basin operations of Texas and New Mexico. Conventional chemical programs deployed for prevention & remediation and hot water treatments for remediation were met with poor success and high operating costs. Paraffin related failures caused the Producer to pull wells prematurely, lose oil production during downtime, handle operational challenges in restoring production in failed wells and cope with high flowline pressures.

The Solution

The Independent Oil and Gas Producer engaged the Enercat Technology Group to install Enercat Downhole Tools for a 130-day trial in 2 wells experiencing extreme paraffin deposition problems. The Enercat Downhole Tool is a novel yet proven technology that lowers Wax Appearance & Pour Point temperatures and impedes the paraffin crystallization process by weakening the intermolecular London Dispersion forces that govern precipitation, crystallization, and wax deposition in paraffinic crudes.

The results of the trial in paraffin prevention in downhole production equipment and at surface flowline facilities were extraordinary. After 30 days post-Enercat installation there was little to no paraffin build-up on the rods and only very slight paraffin forming on steel couplings and rods after 130 days post-Enercat installation. There was no paraffin deposition in surface flowlines at 32 days post-Enercat installation nor at 131 days post-Enercat installation.

Commercial Benefit and Producer’s Endorsement

The leading US Independent Oil and Gas Producer provided the Enercat Technology Group with a post-mortem analysis of the 130-day 2 well trial:

- Conventional chemical programs were not used after the Enercat tools were installed resulting in 100% cost savings.

- No hot water treatments were required to restore production in well failures.

- Flow lines were clean with no paraffin deposition.

- No lost production due to paraffin related downtime.

The Producer enthusiastically endorsed the Enercat Downhole Tool, proclaiming that “it would take years for a paraffin related failure to occur based on the slight paraffin build-up seen on rods after 133 days”.

Moreover, after a thorough evaluation of the Enercat tool’s performance by the chief production engineer in concurrence with the production foreman and rig consultant, the chief engineer declared “I find Enercat tools to be the best paraffin prevention method and should be used as the first line of defense.”

Reducing Paraffin Build-up on Rods

Eliminating Paraffin Build-up in Flowlines

Paraffin Production During Initial Rod Pulling

Oil Production Increases

in Paraffin-Rich Kansas

Tool Installation Program

A small independent Mid-Continent producer installed the Enercat Downhole Tool in 22 of their Kansas stripper wells between April 2019 and September 2021. The wells were experiencing ongoing paraffin deposition causing interruptions to production and costs associated with the need for recurrent hot oiling and chemical treatments. The Enercat tools were not installed for the purposes of a trial; the company was already satisfied with the efficacy of the Enercat Tool in producing their medium light paraffin-rich crude oils. As such the company did not monitor the post-Enercat crude oil production in the weeks following installation of each of the tools but instead measured the production in all 22 wells in March of 2022. Some of the wells therefore produced for more than two and half years after tool installation and most wells produced for more than one and a half years before their production rates were measured.

Results

The results of the Enercat tool installations were highly successful and despite the long delay in measuring the production performance of each of the wells, eighteen of them were still producing above the commencement rate, two remained level and two wells were marginally lower. The overall production increase was 39.3 BOPD or 39.3% higher. These results represent the minimum benefit of the production increases because all wells naturally decline over time and production rates shortly after tool installation would undoubtedly have been much higher.

Company’s Summary

The company provided a general summary of the results of the installation program: In addition to the revenue from production increases, the wells produced free of paraffin deposition and all chemicals and outside interventions were discontinued.

- Cost of the Enercat tools for the 22 wells was approximately $130,000

- The company realized more than $1,000,000 in oil sales revenue due to production increases.

- Operating costs were significantly reduced.

Discussion

Because oil field production declines naturally it is possible to approximate what production rates of the 22 wells would have been shortly after tool installation by understanding the decline rate of the fields from which they produce. The vast majority of the Enercat installed wells produce from the Bemis-Stutts and Hugoton fields. The production decline at Bemis-Stutts field averaged 6% per annum from 2013 to 2021 and 14% at Hugoton field. Taking the average production decline of both fields gives a 10% annual production decline. Applying this average annual decline enables a reasonable back calculation of what each well was probably producing shortly after installation of the Enercat tool. On this basis, the overall production increase was 68.3 BOPD or 66% higher.

Production Response

Production Decline at Bemis-Stutts Field

Production Decline at Hugoton Field

Enercat in the Wild

Enercat tools are used in 24 countries and have recently been adopted by many large U.S. producers as their standard well optimization solution.